Are you confident that the compressed air you use is clean and safe? Poor air quality can cause equipment damage, product defects, and even health risks.

Knowing how to check compressed air quality is essential to keep your operations running smoothly and protect your investments. You’ll discover simple, effective ways to test your air quality and understand what the results mean. Keep reading to make sure your compressed air meets the standards you need.

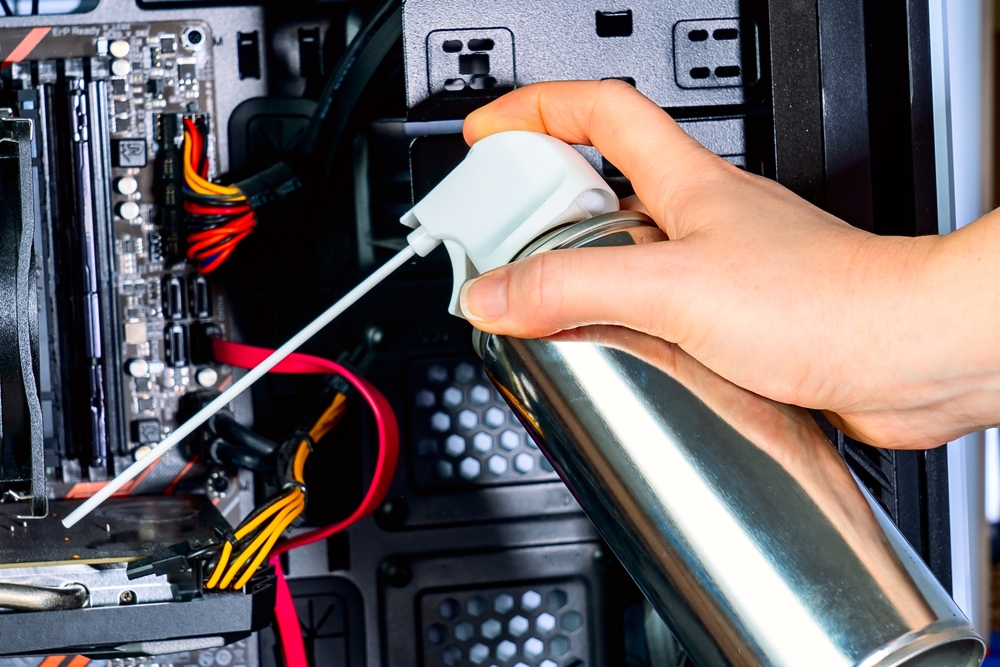

Credit: www.airbestpractices.com

Importance Of Air Quality

Compressed air quality is crucial for many industries. Poor air quality can cause serious problems. It affects machines, safety, and product quality. Checking air quality helps avoid costly repairs and health risks. Understanding why air quality matters is the first step in maintaining safe and efficient operations.

Impact On Equipment

Dirty or wet air can damage equipment parts. It causes rust, corrosion, and wear. Machines stop working properly. Repairs and replacements increase expenses. Clean air keeps equipment running longer and better. This saves money and reduces downtime.

Health And Safety Concerns

Bad air quality can harm workers’ health. Contaminants like oil, dust, or bacteria cause illnesses. Breathing polluted air leads to respiratory problems. Safe air protects employees and improves work conditions. It reduces sick days and boosts productivity.

Industry Standards

Many industries follow strict air quality rules. Standards ensure safety and product quality. Meeting these rules avoids fines and legal trouble. Regular checks help maintain compliance. Standards guide correct air treatment and filtration methods.

Common Contaminants In Compressed Air

Compressed air is used in many industries. Its quality affects product safety and machine life. Contaminants in compressed air can cause damage and reduce efficiency. Knowing common contaminants helps in checking and maintaining air quality. This section explains the main types of contaminants found in compressed air.

Moisture

Moisture is one of the most common contaminants in compressed air. Water vapor condenses inside air systems. It causes rust and corrosion in pipes and tools. Moisture also leads to poor product quality. Removing moisture is important to protect equipment and products.

Oil And Lubricants

Oil can enter compressed air from compressors or lubrication systems. Even small amounts can harm products and machines. Oil contamination affects food, electronics, and painting processes. Filters and separators help remove oil from compressed air.

Particulate Matter

Dust, dirt, and other particles contaminate compressed air. These particles damage sensitive equipment and reduce air quality. Particulate matter can clog valves and nozzles. Using filters prevents particles from entering the air system.

Microorganisms

Microorganisms like bacteria and fungi can grow in moist compressed air. They affect health and product safety, especially in food and medical industries. Proper drying and filtration reduce microorganism growth. Regular cleaning of air systems keeps air safe.

Tools For Air Quality Testing

Testing the quality of compressed air is essential for safety and efficiency. Using the right tools helps detect contaminants and maintain air purity. These tools measure moisture, particles, oil, and pressure levels.

Accurate air quality testing prevents damage to equipment and ensures clean air for processes. Below are common tools used for checking compressed air quality.

Moisture Analyzers

Moisture analyzers measure the amount of water vapor in compressed air. Too much moisture can cause rust and damage machines. These devices show real-time humidity levels. They help keep air dry and prevent corrosion.

Particle Counters

Particle counters detect dust and solid particles in the air. Small particles can clog filters and harm equipment. These tools count and size particles to ensure clean air. They help maintain high air quality standards.

Oil Vapor Detectors

Oil vapor detectors find oil mist and vapor in compressed air. Oil contamination affects product quality and equipment life. These detectors measure oil levels quickly and accurately. They alert users to harmful oil presence.

Pressure Gauges

Pressure gauges show the air pressure in the system. Correct pressure ensures efficient air flow and system performance. Low or high pressure can indicate leaks or blockages. Monitoring pressure helps maintain steady and safe operation.

Step-by-step Testing Process

Checking compressed air quality requires a clear and careful process. This step-by-step testing process helps identify any impurities or issues. Follow these steps to get accurate and reliable results. This way, you maintain system performance and safety.

Sampling Methods

Start by collecting air samples correctly. Use proper sampling points near the air source. Avoid places where air may be contaminated by outside elements. Use clean, dry containers to capture the air. Take multiple samples for better accuracy. This helps represent the air quality throughout the system.

Calibration Of Instruments

Calibrate testing tools before each use. Calibration ensures instruments provide accurate readings. Follow the manufacturer’s instructions for calibration steps. Use standard reference materials or gases. Check calibration regularly during testing. Proper calibration avoids errors and unreliable data.

Data Collection

Record data carefully during testing. Note temperature, pressure, and humidity levels. Use digital devices for precise measurement. Write down all readings immediately. Collect data from all sampled points. Organize data clearly for easy analysis.

Interpreting Results

Compare data with industry standards for air quality. Look for contaminants like oil, water, and dust. Identify any values outside safe limits. Use results to decide if air needs cleaning. Share findings with maintenance teams for action. Clear interpretation helps prevent equipment damage and downtime.

Maintaining And Improving Air Quality

Maintaining and improving compressed air quality is key to efficient system operation. Clean air protects equipment and ensures safety. Poor air quality can lead to costly repairs and downtime.

Regular care keeps the air free from dirt, moisture, and oil. It also helps avoid contamination in sensitive processes. Simple steps can greatly improve air quality and system lifespan.

Regular Maintenance

Check and clean air compressors regularly. Replace worn-out parts quickly. Inspect filters and drains often. Keep the system free from dirt and oil. Scheduled maintenance prevents air quality problems.

Filtration Systems

Use quality filters to remove particles and oil. Change filters as per manufacturer advice. Multi-stage filtration works best for clean air. Proper filtration reduces contamination risks and protects equipment.

Drying Techniques

Remove moisture using dryers or air coolers. Choose between refrigerated and desiccant dryers. Dry air prevents rust and corrosion inside pipes. Proper drying improves air quality and system life.

Leak Detection

Find leaks using ultrasonic detectors or soap solution. Fix leaks immediately to prevent air loss. Leaks lower air pressure and reduce efficiency. Regular leak checks save energy and maintain air quality.

Credit: www.cs-instruments.com

Common Challenges And Solutions

Checking compressed air quality can be tricky. There are common problems that many face. Knowing these issues helps find quick fixes. This section explains typical challenges and how to solve them. It focuses on inconsistent readings, equipment limits, and environment effects.

Inconsistent Readings

Air quality tests can show different results at times. This happens due to poor sensor placement or unstable air flow. Small changes in pressure or temperature affect readings too. To fix this, place sensors in steady spots. Take multiple samples and average them. Regularly calibrate your testing tools for accuracy.

Equipment Limitations

Not all devices detect every type of contaminant. Some tools miss fine particles or moisture. Low-quality sensors can give false data. Use equipment designed for your specific needs. Upgrade tools as technology improves. Train staff to use equipment correctly. This reduces errors and improves data trust.

Environmental Factors

Dust, humidity, and temperature changes affect air quality tests. Nearby machines or vents can also interfere. Keep testing areas clean and controlled. Avoid testing near heavy equipment or air drafts. Monitor room conditions during tests. This helps get clear and reliable results.

Credit: westairgases.com

Frequently Asked Questions

What Is Compressed Air Quality?

Compressed air quality measures the cleanliness and dryness of air in a system. It ensures no contaminants like oil, water, or particles affect performance. High-quality air protects equipment and maintains product integrity.

How To Test Compressed Air Quality?

Use specialized equipment like particle counters, moisture analyzers, and oil detectors. Regular sampling and lab tests also help identify contaminants. Testing frequency depends on application and industry standards.

Why Is Compressed Air Quality Important?

Poor air quality can damage tools, cause product defects, and increase maintenance costs. Clean air improves efficiency, extends equipment life, and ensures safety in sensitive environments.

What Contaminants Affect Compressed Air Quality?

Common contaminants include water vapor, oil aerosols, dust, and bacteria. These impurities reduce system efficiency and can harm machinery or final products.

Conclusion

Checking compressed air quality keeps machines running well and safe. Regular tests spot dirt, water, and oil in the air. Good air quality helps avoid damage and cuts repair costs. Use simple tools and follow steps to check air quality often.

Clear, clean air means better work and fewer problems. Don’t wait for issues. Stay ahead with easy air checks. Your equipment and team will thank you.

Daniel Hart is a consumer product analyst who specializes in mattress technology, smart bedding, and home comfort innovation. Before joining Royal Comport, Daniel worked with several e-commerce research teams, testing and comparing sleep products for quality, value, and long-term performance. He brings data-driven insight and real-world testing to every review he writes.